How much do you know about Iron Distribution Boxes?

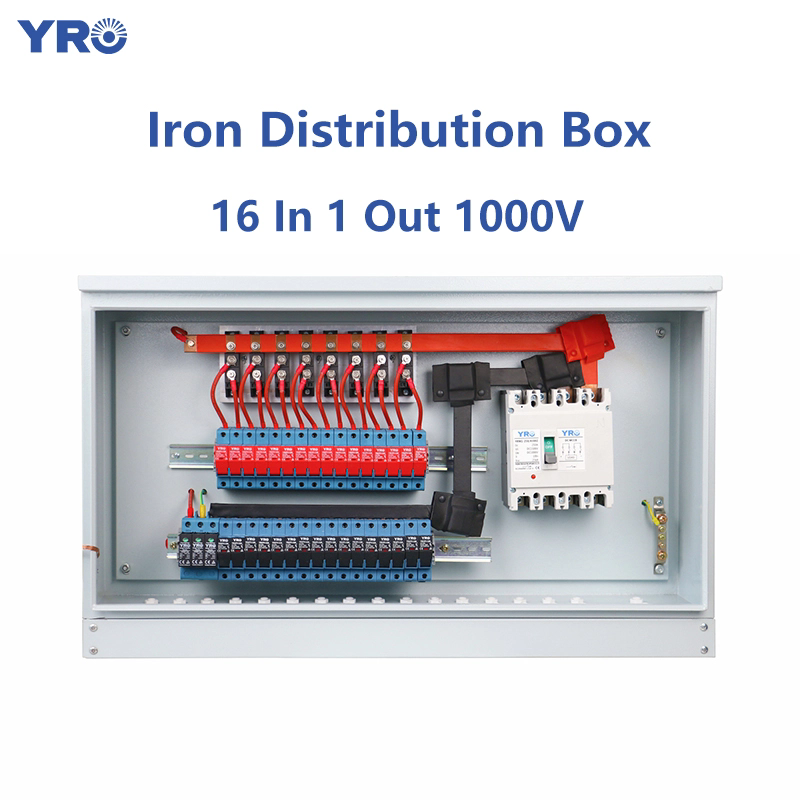

For decades, the reliable distribution of electricity in industrial, commercial, and residential environments has relied on a critical component: the Iron Distribution Box. As the cornerstone of electrical management systems, these enclosures protect connections, circuit breakers, and terminals from environmental hazards, ensuring safety and operational continuity. YRO has established itself as a leader in this field with years of expertise in manufacturing and supplying a wide range of high-quality iron distribution boxes. Our products are designed to meet the rigorous requirements of applications ranging from large industrial plants to specialized utility projects.

Core Features

An Iron Distribution Box, commonly known as a junction box or distribution box, is a rugged enclosure that houses electrical connections, circuit breakers, fuses, and other components. Made primarily of iron (typically galvanized steel or cast iron), it offers exceptional strength and durability.Here are some examples of its use cases.

| Application Sector | Specific Use Case | Environmental Challenges | Key Reasons for Suitability |

| Industrial Manufacturing | Main power distribution and motor control centers (MCCs) on factory floors. | Dust from production, vibration from machinery, occasional impact from equipment, humidity, and water splashes during cleaning. | High mechanical strength withstands impact and vibration; IP54/IP65 rating protects against dust and water jets; DIN-rails organize breakers and contactors. |

| Construction & Infrastructure | Temporary site power distribution, housing connections for tools and site lighting. | Exposure to rain, dust, mud, extreme temperatures, and potential physical abuse or impact on busy sites. | Heavy-gauge steel construction resists physical damage; IP66/IP67 rating ensures functionality in heavy rain and dusty conditions; robust locking mechanisms enhance security. |

| Water & Wastewater Treatment | Controlling pumps, valves, and sensors in pump stations, filter rooms, and outdoor basins. | Persistent high humidity, condensation, direct water exposure, prolonged immersion in flooded pits, and corrosive chemicals (chlorine, hydrogen sulfide). | IP68/IP69K ratings guarantee protection against prolonged immersion and high-pressure wash-downs; cast iron and hot-dip galvanized finishes offer superior corrosion resistance. |

| Energy & Utilities | Housing connections for street lighting, traffic signals, and fiber optic network nodes. | Outdoor exposure to UV radiation, wide temperature fluctuations, rain, snow, and vandalism. | Powder-coated finish resists weathering; lockable handles prevent unauthorized access; robust material deters vandalism. |

Key Benefits

High Durability and Strength: The iron construction is highly impact-resistant, protecting sensitive electrical components from physical damage.

Excellent Protection: The Iron Distribution Box is highly resistant to dust, moisture, and corrosion, especially when treated with coatings such as powder coating or hot-dip galvanizing. Heat Resistance: Iron can withstand higher temperatures than many plastic alternatives, making it ideal for high-load applications.

EMI Shielding: Iron's magnetic properties provide a degree of electromagnetic interference (EMI) shielding, which is critical in environments with sensitive electronic equipment.

Long Service Life: A well-crafted iron box is a long-lasting asset, able to withstand years of wear and tear.

Iron Distribution Box FAQs

Q: What are the main differences between IP65 and IP68-rated iron distribution boxes? How do I choose?

A: The IP (Ingress Protection) rating is a two-digit code that defines the level of protection against solid particles and liquids. The first digit represents the protection against solid particles (6 is the highest rating, meaning "dust-tight"). The second digit represents the protection against liquids.

IP65: The "5" indicates protection against water jets from any direction. It is suitable for outdoor applications where the distribution box may be exposed to rain or hosed down directly but not submerged.

IP68: The "8" indicates protection against extended immersion under specified pressure and time conditions. This rating is crucial for applications where the distribution box may be flooded or installed in pits, manholes, or other locations prone to water accumulation.

Your choice should be based entirely on the environment. For factory floors that require occasional cleaning, IP65 is generally sufficient. For wastewater treatment plants or underground utility vaults, IP68 is essential to ensure long-term reliability and safety.

Q: Can I customize the interior layout of the Iron Distribution Box? For example, by adding additional DIN rails or specific mounting holes?

A: Yes. YRO supports customization to meet your precise needs. You can request the following modifications:

Addition of DIN rails in various sizes (35mm, 32mm, 15mm).

Custom drilled and tapped holes for mounting specific components, such as PLCs, terminal blocks, or transformers.

Addition of internal subpanels or partitions to separate high- and low-voltage components.

Specific openings in the door for mounting windows, instruments, or control switches. We encourage you to provide a detailed diagram or component list, and our engineering team will propose the best internal layout for your iron distribution box to ensure easy installation and maintenance.