What are the advantages of using the ABS Distribution Box?

2025-09-10

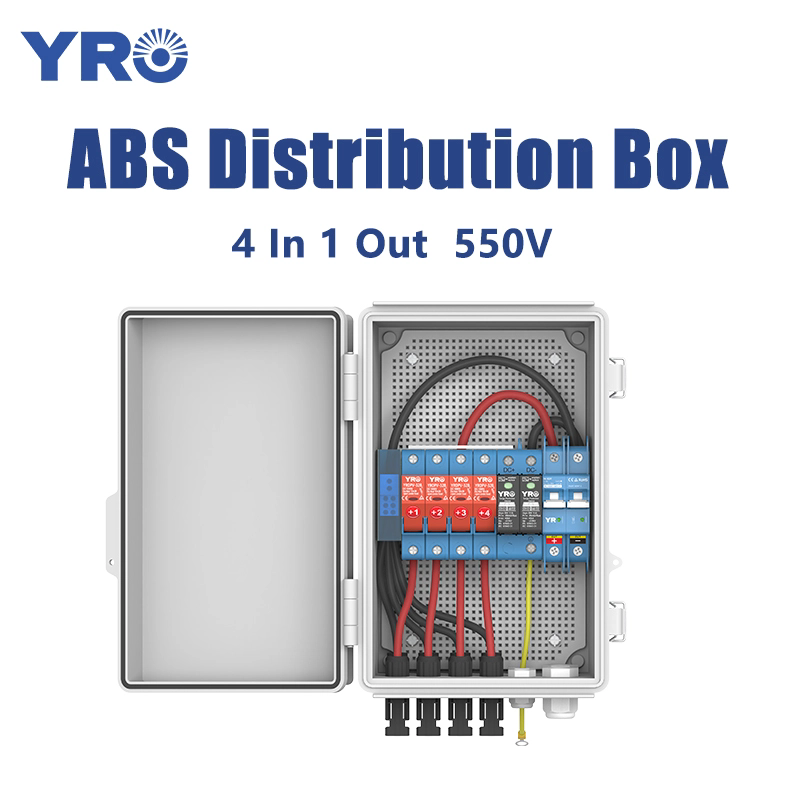

In the intricate field of electrical systems, safety, reliability, and durability are of paramount importance. Selecting the appropriate enclosure to house connections, terminals, and protective devices is a crucial step. Zhejiang Yongrong New Energy Co., Ltd. (YRO), with its profound expertise in electrical components, is dedicated to manufacturing high-quality ABS Distribution Boxes to meet the diverse application requirements of customers worldwide, particularly in the demanding photovoltaic (PV) sector. What are the advantages of using ABS distribution boxes? Let's take a closer look.

Durability

The material is selected as ABS plastic, which has excellent impact resistance, wear resistance and physical stress resistance. It has many advantages when used to make the shell. The inherent toughness of this material ensures that the distribution box and its key internal components are protected from accidental impacts, vibrations during transportation or operation, and general wear and tear over many years of use.

Weather Resistance

Ultraviolet radiation: In outdoor solar energy applications, protection against ultraviolet rays is a crucial factor to prevent embrittlement, fading, and performance degradation caused by prolonged exposure to sunlight.

Moisture and humidity resistance: With a high ingress protection rating, it ensures reliable sealing to prevent the intrusion of dust and water jets, thus avoiding corrosion and electrical faults.

Wide temperature range: It maintains structural integrity and performance even under extreme temperature fluctuations commonly found in outdoor electrical environments.

Chemical resistance: It has good resistance to a variety of solvents, oils, and weak acids commonly found in industrial environments.

Electrical Safety

ABS is an excellent electrical insulator with high dielectric strength, which can essentially reduce the risk of electric shock or short circuit. Many grades also have inherent flame retardant properties, which are crucial for controlling potential electrical fires.

Lightweight and Easy to Install

The ABS Distribution Box is much lighter than metal enclosures, which can reduce transportation costs and make the operation and installation by technicians quicker, simpler and safer, especially in elevated or hard-to-reach locations. This means less labor time and cost.

Flexible and Aesthetic Design

ABS plastic can be easily molded into complex shapes, enabling a fashionable and modern design, and optimizing the internal layout for convenient component installation and cable management. Its smooth surface is not only aesthetically pleasing but also easy to keep clean.

Cost-Effectiveness

The ABS Distribution Box boasts high material efficiency, lower manufacturing costs than metal, light transportation weight, and easy installation. It achieves an outstanding total cost of ownership without compromising performance and safety.

| Feature | Typical Specification Range | Notes |

| Dimensions (HxWxD) | 200x150x100mm to 600x400x200mm | Custom sizes readily available. |

| IP Rating | IP65 (Standard), IP66, IP67 (Optional) | Ensures protection against environment. |

| Material | High-Impact UV-Stabilized ABS (UL94 V-0) | Guarantees durability & safety. |

| Color | Light Grey (RAL 7035), Black | UV-stabilized for outdoor longevity. |

| Operating Temp. | -40°C to +85°C (-40°F to +185°F) | Reliable performance in extreme conditions. |

| Mounting | DIN Rail (EN 60715 TH35), Panel Mount, Wall | Flexible installation options. |

| Transparency | Clear Lid Options Available | Allows visual inspection without opening. |

| Cable Entries | Multiple Knockouts (Φ16mm, Φ20mm, Φ25mm) | Easy cable gland installation; various entry positions. |

| Certifications | CE, RoHS, TUV, CB (Model specific) | Compliance with international safety & environmental standards. |