What Is a Disconnector Switch, and How Does It Work?

2025-04-18

During routine maintenance of power systems, technicians frequently encounter a challenging situation: How to safely interrupt electrical flow when servicing equipment, while preventing accidents like arc flashes or explosions due to operational errors?It is precisely based on this actual situation that the disconnector, a dedicated device, has been developed and applied.

What Is a Disconnector Switch?

A disconnector switch is a mechanical device used in electrical systems to ensure that circuits are completely disconnected. Its main function is to provide visible physical isolation when equipment is under maintenance or malfunctions, prevent accidental power-on, and ensure the safety of operators. One point to note: It is usually not used for the on off operation of the load current, but serves to "isolate the power supply".

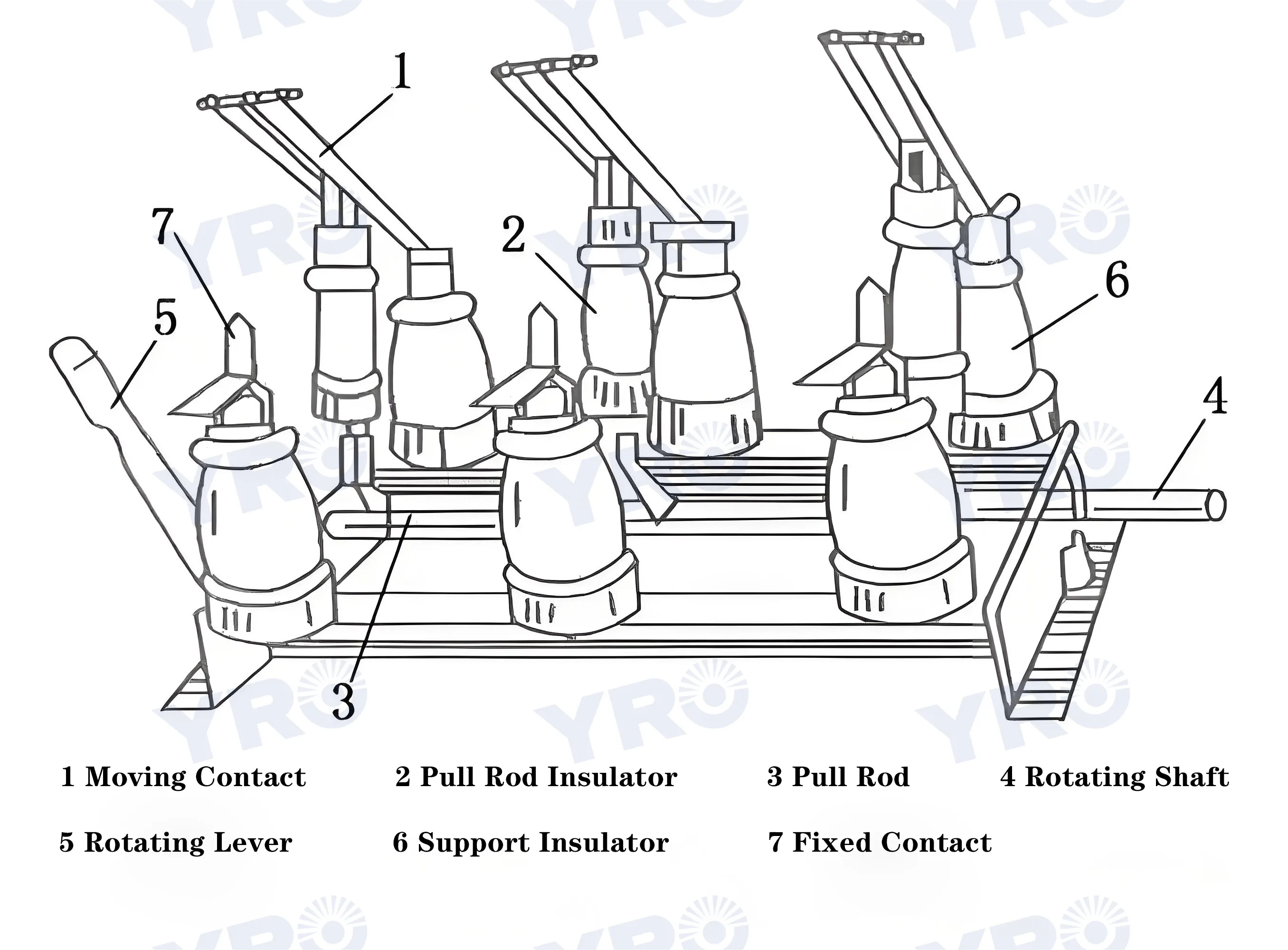

The disconnector, also known as the disconnector knife switch, is essentially a metal contact system with an insulating support structure. Unlike circuit breakers, it does not have arc-extinguishing capability, which means it is prohibited to operate under load; otherwise, the equipment may be burned out under high voltage.

How Does a Disconnector Switch Work?

1. Opening operation:

Step 1: Confirm that the circuit breaker has been disconnected and there is no load current in the circuit.

Step 2: Drive the moving contact to rotate or translate through the operating mechanism, separating it from the static contact to form a visible fracture surface.

Step 3: After the contacts are separated, the break distance should meet the insulation requirements (for example, in a 10kV system, it should be ≥150mm) to ensure that no current passes through.

Step 4: Lock the open position and confirm the status through a mechanical indicator or electrical signal.

2. Closing operation:

Step 1: After checking that there are no abnormalities in the circuit, remove the interlock device.

Step 2: The operating mechanism drives the moving contact to make close contact with the static contact, ensuring the contact pressure (such as being compressed by a spring) to reduce the contact resistance.

Step 3: Enhance stability through contact clamping design (such as double blade structure) and electromagnetic lock (in high short circuit current scenarios).

What Are the Unique Functional Features of Different Types of Power Disconnectors?

Classified by voltage level

High voltage disconnector switches: It is used in high voltage power systems of 10kV and above, and is usually installed between substations or distribution transformers. It has a complex structure and requires strong insulation performance and mechanical strength.

Low voltage disconnector switches: It is used in AC 220V/380V and DC systems, widely applied in industrial electrical cabinets and photovoltaic junction boxes. It features a compact structure and simple operation.

2. Classified by structural form

Knife switch type disconnector: It is shaped like a metal blade and achieves on off by inserting or pulling it out. It is usually used in low voltage systems and is the most intuitive form.

Rotary disconnector switches: By rotating the operating handle, the internal contacts are closed or opened. It is suitable for scenarios with limited space and is often used on mechanical control panels.

Drawer type disconnector: Installed in drawer type switch cabinets, it is convenient for maintenance and replacement and is often used in power distribution systems that require frequent operation.

3. Classified by installation method

Indoor disconnector: It is used in indoor environments and is designed with a greater emphasis on compact structure and dust-proof capability.

Outdoor safety cut off switch: It is suitable for outdoor environments such as outdoors or on rooftops, and needs to have good rainproof, UV-proof and anti-corrosion performance.

4. Classified by operation mode

Manual power disconnector: The mechanical connecting rod is driven by an insulated operating lever or a rotating handle to separate the contacts. This method is mostly used in low voltage or small scale power distribution systems.

Electric operation: The opening and closing of the switch are accomplished by driving the gear mechanism with an electric motor, which is commonly seen in scenarios such as high voltage substations that require remote control.

Conclusion

Although the disconnector is not the most complex electrical equipment, it is an important component for ensuring personal safety and the stable operation of the circuit system. From the basic definition to the working principle, and then to the functional differences among various products, we can see that choosing the appropriate disconnector can not only improve maintenance efficiency, but also significantly reduce the accident rate.

If you still want to delve deeper into a certain model or installation case, YRO can further analyze the actual application situation for you or recommend suitable products. If you need any assistance, please feel free to contact us