How Does a Disconnect Switch Prevent Backfeeding of Grid and Generator Power During Dual Power Switching?

2025-12-13

In power supply systems that use both municipal electricity and generators, the safe switching of power sources is an operational requirement that must be strictly adhered to. During the process of dual power supply switching, reverse power supply is a risk that requires special attention. If electrical energy flows in reverse from one power source to another, it will pose a threat to personnel safety, cause equipment failure and bring about compliance issues.

Why Must Dual Power Transfer Switches Absolutely Prevent Backfeeding?

Backfeeding occurs when two independent power sources become interconnected, causing current to flow in unintended directions. Assume a thunderstorm causes a building-wide power outage, and the building manager starts the backup generator, but incorrect switching operation allows electricity to flow backward into the utility lines that should be dead. This phenomenon is backfeeding, which creates invisible dangers for grid maintenance personnel. Furthermore, when the grid power is suddenly restored, the generator may be subjected to abnormal voltage surges, potentially causing damage to the generator.

How to Solve the Problem of Safe Dual Power Switching?

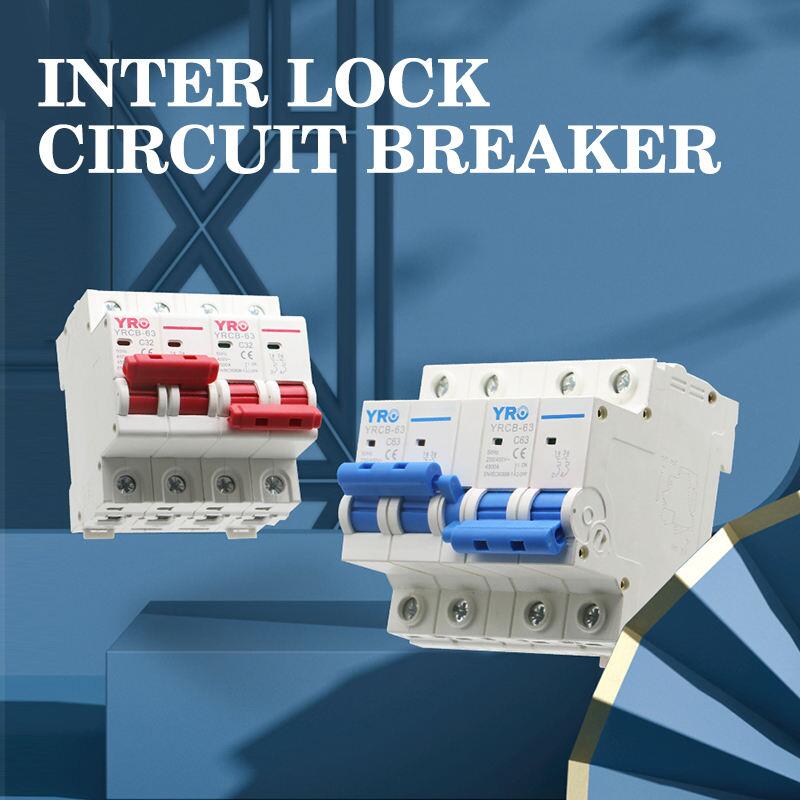

Mechanical Interlock

Mechanical interlocking is one of the most fundamental yet crucial safety designs in dual power isolation, and its working logic is very straightforward:

- Only one power supply can be connected at any time.

- When one power supply is in the closed state, the other side is structurally forced to lock.

- It eliminates the possibility of two power sources being connected in parallel from a physical perspective.

This design approach ensures that even if the operator makes a mistake, there will be no instantaneous situation where the two power supplies are connected in parallel or in reverse.

Disconnect Switch

In dual power switching applications, the disconnect switch does not merely serve the function of "making or breaking current." Its core value lies in using its mechanical structure to forcibly achieve power source isolation.

When the contacts of the disconnect switch are in the "Open" position (the blades are raised), an open circuit is formed, and current cannot pass through. When in the "Closed" position (the blades are lowered), a closed circuit is formed, allowing current to flow freely between the two sides. This hardware-based approach significantly reduces the possibility of backfeeding occurring due to operator error or abnormal conditions.

Compliance, Acceptance, and Long-term Reliability

From the perspectives of acceptance and maintenance, disconnectors still have obvious advantages. Its clearly visible disconnected state enables inspectors to intuitively confirm whether the system has achieved effective isolation.

From a long-term operational perspective, reliable physical isolation also helps to reduce the electrical shock that equipment is subjected to, enhance system stability, and extend the overall service life.

Conclusion

In any dual power supply system that uses both mains power and a generator, preventing reverse power supply between the two is a fundamental safety requirement. When the disconnector is used in conjunction with an appropriate interlocking device, it can provide a fundamental guarantee for achieving this safety function.

Whether choosing a simple mechanical interlock for a residence or an automatic conversion system for a critical location, the basic working principle is similar: before connecting one power source, it is first physically and visually confirmed that the other power source has been completely disconnected.

Power switching is not only for maintaining uninterrupted power supply, but also related to whether electrical energy is always transmitted along a safe and correct path.